en

The ceramic cartridge is the heart of the faucet, and the ceramic disc is the heart of the cartridge. All components of WANHAI cartridges are produced in-house and the discs are handled with the utmost care, so every step of the production must be fully controlled to ensure that the finished product is accurate, durable and reliable.

It first selects the best raw material made by dry pressing, sintering process in high temperature oven, grinding, cleaning, drying and final surface inspection.

Seals are also produced in-house, including material mixing, stamping and vulcanization.

No third-party suppliers of components are involved, only select raw materials sourced from around the world go into the factory.

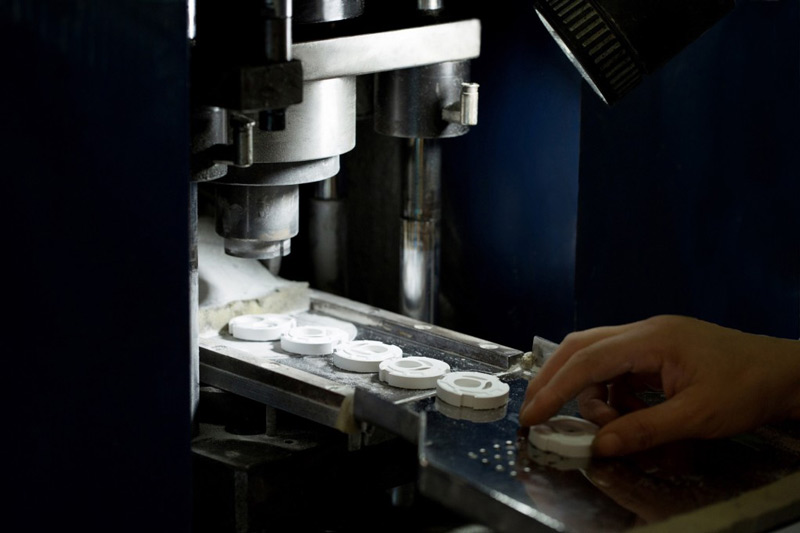

Dry pressing with high-quality German raw materials

Material hardens during sintering, 18 hours at 1650°C

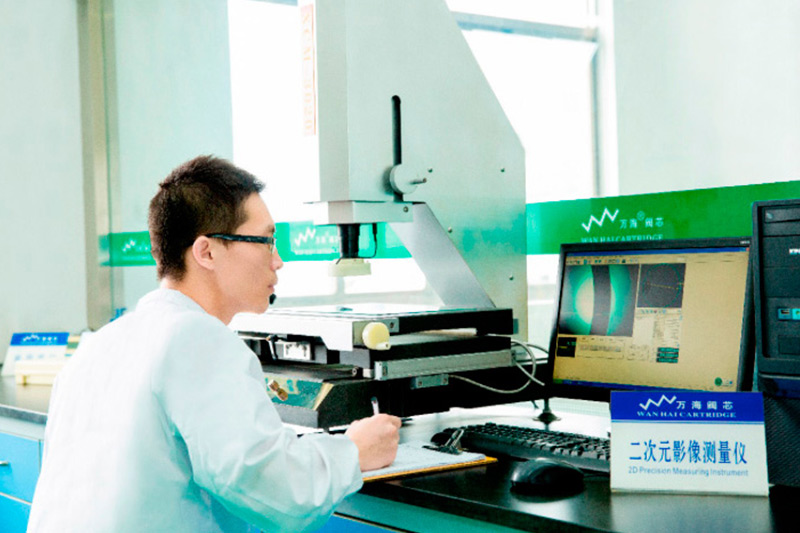

Any defective discs found this way are removed from the production line and discarded

The disc is ground on both sides

Disc polishing, minimum 25 minutes for bottom and 18 minutes for top surface

more polishing of the surface

Cleaning discs by ultrasonic

The operator checks the ceramic discs to see if they are suitable for the next step

The compound produces

Plastic material is formed by machine

Gaskets are vulcanized

The gasket is scraped clean

Check the part for the next step

The cartridge plastic shell is injected

Ceramic cartridge parts assembly, 7 workers per line

Dynamic Pressure Test of Cartridges

Each cartridge is leak-tested before items are packaged

Quore ceramic cartridges are ready to ship

Oven Lines

Machine Dry Presses

Different Polishing Stations

Injection Molding Machines

Different Machines in the Test Center